MEANDER REFIT MK2 PART 3 (15 OCT 2014)

A long-overdue update for you all…

I spent 10 days in Barcaldine just recently to progress the installation of the new engine and continue with the coachroof repairs. When I left the boat in August, I had just managed to start the laborious process of fairing the repairs to the top of the coachroof using copious quantities of epoxy filler. I had also given the new sides 3 coats of epoxy resin for waterproofing, and in the nick of time, the very evening before I left, managed to reinstall the windows, thus leaving the boat somewhere approaching watertight, in case the shed developed any new leaks!

Stu and his dad Dave drove up from Brum to collect the caravan, and we drove down in convoy, before I continued on the last bit to Gosport on my ownsome.

After a brief interlude during which I brought Lord Nelson back home from Halifax, Nova Scotia (with all the attending press interest and parties) to London, I headed up once again, looking forward to seeing my shiny new engine, and getting it installed.

To help me in this task, for the first couple of days anyway, friend Callum Jones had made himself available with his marine engineering expertise. Due to the movements of other boats into the shed, the Beta agent had already had the engine craned into the boat, so when we arrived it was sitting in the engine bay, and it became obvious straight away that there were two problems. Firstly, whilst it was at roughly the correct height, it was sitting on its sump in the bottom of the engine tray; secondly, the feet that the agent had had specially adapted did not line up with the engine beds. Whilst we scratched our heads and thought about this, we started to look at the services, and immediately noticed that the new Morse cables and fuel filters had not been delivered. I contacted the agent and he said he’d get the bits as soon as he could, and his ideas for getting the engine to fit were that I should start chiselling away at the boat’s structure to shoehorn it in. Not a terribly satisfactory answer. More head-scratching…

So Callum and I pottered about removing the old Morse cables and control lever, and went on a search for 8mm copper fuel hose as well as other bits and bobs, some more successfully than others. The bits we couldn’t find I had to order from my normal Techie supplier ASAP Supplies.

As we were still waiting for the bits that hadn’t arrived, Callum felt after 2 fairly abortive days that he could do no more; meanwhile on my third day I whizzed up to Forres in Morayshire for the day to attend a memorial service for the mother of one of my oldest friends, so little progress was made.

Finally on the Friday, the bits arrived, and I was able to crack on with some fairing on the coachroof, as well as fitting the timber trim to finish off the woodwork. That evening, Team Phillips (Mum and Dad) joined me, and in the evening we moved into the rental cottage I had found just down the road at Barcaldine House.

Over the weekend my father and I stared at the engine and its mounting arrangements, and, deciding they were unsatisfactory, I contacted the agent with an ultimatum to make things good by supplying and fitting a shallow sump (a standard option) and remaking the feet so they align with the engine beds, both to be done free of charge. Meanwhile, we continued looking at the services and controls, installing the Morse cables and control lever, instrument panel and wiring loom, and looking in detail at the cooling system and fuel supply system. We also finished and prepped the final bits of woodwork on the coachroof ready for painting.

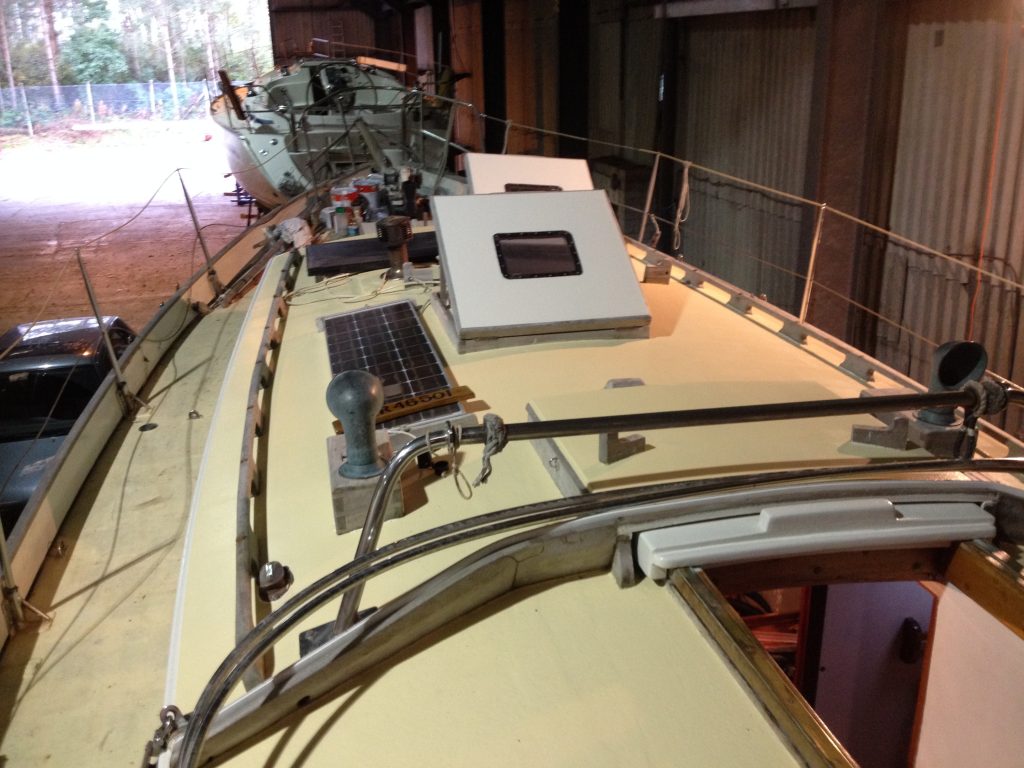

The Beta agent arrived on the Monday morning, and immediately agreed with my demands, and I also clarified a couple of other points, and commissioned him to bolt down and align the engine, thus reducing the amount of work I need to do. For the rest of the week we concentrated on the coachroof, painting the outside with two coats of epoxy primer, followed by two of topcoat, whilst inside we gave the new sides a further coat of epoxy primer (the first was applied before the sides were fitted), followed by a coat each of good old Dulux undercoat and off-white topcoat. Meanwhile the Spar Fairy (aka Mother) wore away her fingerprints sanding the patches on all my spars which had signs of damage, and then giving them a couple of coats of varnish.

The last day was a day of frantic painting, and then once the topcoat was touch dry (fortunately a quick process with this particular type of paint), again frantic bolting on of all the fittings which had had to be removed at the start of the job. As a result, the coachroof job is as good as finished, with just some interior fittings to re-fit, and the engine awaits the attentions of the agent. When we return after Christmas, it should be ready for the attachment of all the services and then we can run it up for the first time. Can’t wait!